With the continuous progression of implant therapy many dentists devote their time and resources to simplify clinical methods and improve services. Familiar tools used for clinical practice like stock abutments are slowly being replaced by technological innovations like custom abutments, also known as patient specific abutments, to enhance the restorative process. The main purpose of these changes is to improve the outcomes of implant therapy and to better serve patients. The dentist who uses efficient and effective tools is expected to have an increased number of patients compared to those who use conventional tools.

Stock Abutments

It refers to pre-made titanium abutments which are either refined in the lab or at chairside before doing a crown fabrication. It is called by the following names:

- preparable

- easy

- direct

Features:

May be burnished to customize them for the specific case at:

- laboratory

- dental office

Available as:

- straight

- pre-angled

Procedure

A dentist using stock abutments usually follows the steps below:

- chooses a specific stock abutment

- makes modifications

- delivers the abutments to place

- Prepares for fabrication and final prosthesis by making a traditional crown and bridge impression

Recent stock abutments have improved designs to facilitate the following:

- improved emergence contours

- reduced lab preparation time

- accurate transfer of the abutment positions (through pre-fit impression copings)

These new advancements in stock abutments seek to achieve the following:

- Enhanced crown contours and overall abutment

- Improved clinical and lab efficiency

Benefits of stock abutments

- Less costly than custom abutments

- Saves time

Disadvantages of stock abutments:

- Major modifications are impossible because of the following reasons:

- Weakening of the abutment structure

- Angles supplied may be-

- too great

- not great enough

- Angle compared to hex orientation may not perfectly align

- Emergence profile may not be sufficiently wide to give a natural look

- It cannot follow the contours of your soft tissue

- You cannot add to it if it is deficient in an area

- Oftentimes, you have to prep it or subtract from it.

The need for custom patient specific abutments:

Through the years, dentists are looking for predictable, cost effective and efficient way of replacing or restoring teeth. Implants are usually placed in between your patients’ existing natural teeth and into extraction sites. These implants should have the esthetic and functional values which are different from traditionally placed implants. In cases where a dentist wants to use abutments which specifically designed for a patient’s individual needs and expectations, the Atlantis™ Abutment solution is a great choice.

Why Atlantis specific abutment is necessary

Nowadays, most patients want functionality and esthetic value for their abutments. They want their implant restorations to function well and to look like and blend with their adjacent natural teeth. Abutment – the foundation of teeth restoration is a critical factor in creating a crown which has a natural look. The way your patients’ implant emerges (emergence profile) through their soft tissue into their oral cavity, establish whether their implant restoration will have the appearance of a natural tooth or not. The prosthetic abutment determines the contour.

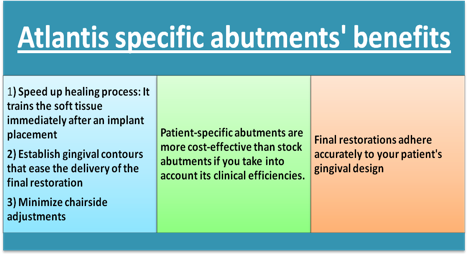

In general, custom made (specific) abutments are better than stock abutments because they are already modified in the lab and specifically designed to meet your patient’s unique needs before your patient’s prosthetic crown is fabricated.

Another problem with stock abutments is the fact that they are manufactured based on the diameter of the implant platform being restored, not according to the exact size and shape of the replacement crown it needs to support or the tooth being replaced. Consequently, most dentists have no choice but to use the same abutment for different restoration.

The solution

Atlantis™ Patient-Specific Abutments is a simple solution that offers functionality and esthetic value which are lacking in a stock abutment. Atlantis Abutments have unique designs for each implant suited for the patient’s mouth.

Atlantis uses 3D imaging and Virtual Abutment Design software, which enables it to design its abutments based on your patient’s final tooth shape. This process also integrates your design parameters.

For example, you can specify the following:

- margin design

- subgingival depth

- whether your patient’s abutment has a retentive surface or not.

The abutment is designed in a virtual environment to create an ideal and specific abutment for your patient. There is no need for hands-on work, waxing or milling by your dental technician because the process is completed digital.

You can also order many abutments which replicates the original abutment if you need a replacement abutment at a later date without needing a new impression.

You can alter the duplicate abutment to make up for changes in your patient’s soft tissue margin surrounding the implant. As a result, you don’t need a new impression or the abutment does not have to be modified intra-orally.

With recent innovation in dental technology, implant surgery becomes easier with the use of computed tomography scans that provide 3-dimensional images for the dental surgeon to evaluate the patient’s bone morphology before placing the implant. It creates surgical templates showing the most suitable bone to place the dental implant.

If you’re specializing on implant dentistry, you can expect to meet these two challenges during the surgery:

- Immediate loading- placement of a functional fixed or removable restoration

- Immediate provisionalization-placement of a temporary restoration

After the surgery, you have to watch out for some potential dental implant problems:

- Infection

- insufficient bone mass

- incorrect positioning

- fractured implants

- damage to surrounding tissue

- overloading

- reaction to anesthesia

However, if you are using specific abutment, problems 2 to 6 are very unlikely to happen. It is also important to note that over 95% of dental implant cases are completed without complications.

Feel free to call our customer service at (800) 361-1659 for any question.